PMM Wing Service – Official Champion Slick Magneto Service Center

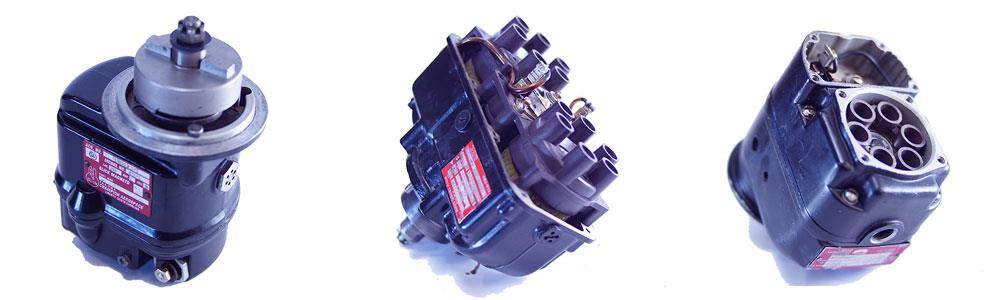

We are proud to announce that PMM Wing Service is an official service center for the repair, overhaul, exchange and warranty of Champion Slick magnetos.

We can offer you:

- A repair service for your Champion magneto’s

- Overhauled magneto’s in stock for exchange

- 500Hrs inspection of your magneto

- Warranty repair or replacement of your Champion magneto

Magneto Exchange Program – Minimize Downtime

Why Choose Us?

- Certified and experienced magneto specialists

- Fast turnaround times

- Access to a wide range of exchange units in stock

- Competitive pricing with no compromise on quality

- Every unit is bench-tested and comes with a EASA FORM 1 dual release

Whether you're looking to repair your current magneto or swap it for a tested and ready-to-go unit, we’ve got you covered. You can find us on the official Champion Aerospace website.

500-Hour Magneto Inspection and repair

To ensure optimal performance and safety, aircraft magnetos must undergo a detailed inspection every 500 flight hours. At our facility, we follow a rigorous process to thoroughly check and service each magneto that arrives for inspection.

Disassembly and Inspection

Upon arrival, the magneto is completely disassembled. Every component is carefully inspected and measured for wear and tolerances. This step is crucial for identifying any early signs of damage or degradation.

Component Servicing

Next, the distributor block bushing is coated to ensure smooth operation and longevity. We then install new contact points and high-tension brushes, replacing the old parts with only high-quality components that meet OEM specifications.

Compliance Check

All applicable Airworthiness Directives (ADs) and Service Documents (SDs) are reviewed and strictly followed. If updates or modifications are required, they are implemented at this stage to ensure full compliance with aviation safety regulations.

Reassembly and Testing

After all components have been serviced or replaced, the magneto is reassembled with precision. Finally, it undergoes a full function test on our certified test bench to verify correct operation under simulated engine conditions.

This comprehensive 500-hour inspection guarantees that your magneto is safe, reliable, and ready for continued operation.

Every inspected or repaired magneto is delivered with a dual release EASA/FAA Form 1 certificate, meeting the highest international aviation standards.

Overhaul

Need a quick solution? Take advantage of our Magneto Exchange Program. We maintain a well-stocked inventory of fully serviced and tested magnetos, ready to ship immediately. Simply order your replacement magneto and send us your core magneto after replacement.—saving you valuable time and getting you back in the air faster.

All magnetos are thoroughly inspected, and any necessary parts are replaced using genuine Champion components.

The parts that are replaced during an overhaul are:

- Capacitor,

- Double sealed bearing,

- Bearing cap assembly,

- Coil,

- Oil seal,

- Contact point kit,

- Rotor gear,

- Distributor block and gear,

- Woodruff key(s)

- Cotter pin, Washer,

- Impulse coupling (if installed),

- Impulse coupling spring (if installed).

After reassembly, each unit is rigorously tested on our certified test bench to ensure optimal performance and reliability.

Finally this magneto will get a new personalized data plate (with the original serial number).

Every overhauled magneto is delivered with a dual release EASA/FAA Form 1 certificate, meeting the highest international aviation standards.

For more information or to schedule a service, please don’t hesitate to contact us.

Need a quick solution? Take advantage of our Magneto Exchange Program. We maintain a well-stocked inventory of fully serviced and tested magnetos, ready to ship immediately. Simply order your replacement magneto and send us your core magneto after replacement.—saving you valuable time and getting you back in the air faster.